TSP / TSPL NTSUG TXOJ KEV TWJ

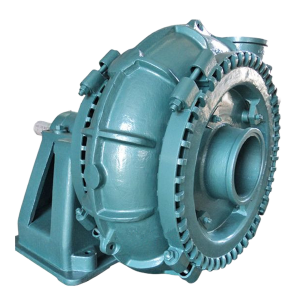

TSP / TSPL NTSUG TXOJ KEV TWJyog tsim rau cov ntawv thov uas yuav tsum tau ua kom muaj kev cia siab ntau dua thiab lub cev nruj dua cov txheej txheem tuaj yeem muab. Tag nrho elastomer lined los yog hard hlau fitted. Tsis muaj submerged bearings lossis ntim. Muaj peev xwm kev muaj peev xwm tsim qauv. Mekas submerged ntev thiab suction agitator muaj. Lub tsp / TSPL Ntsug Sump Twj Tso Kua Ntseg ua rau muaj cov dej tsis sib haum thiab cov kua uas tau hais plaub thiab cov kua zaub uas zoo nkauj.

Tsim nta

Kev nyab xeeb me me, tsawg dua corrosion

Wetted Cheebtsam muaj nyob rau hauv ntau cov alloys thiab elastomers, los ntawm cov khoom siv ua tau zoo thiab corrosion ua ke nrog cov khoom lag luam loj dua lossis qhov siab qeeb los yog ntsib.

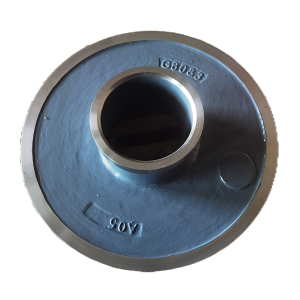

• Puas kam tiv taus A05 Ultrachrome® Alloy.

• Puas yog tshem tawm / corrosion-resistant A49 hyperchrome® alloy.

• Corrosion-resistant stainless hlau.

• ntuj thiab hluavtaws elastomers.

Tsis muaj bearerged bearned

Tus muaj zog cantilever ncej kom tsis txhob muaj qhov qis submerged bearings - uas feem ntau yog cov kabmob tsis ua haujlwm tsis ua haujlwm.

• Cov kav dej hnyav rau cov menyuam cov kabmob, saum toj kawg nkaus mountinging.

• Tsis muaj bearmerged bearings.

• Labyrinth / Flinger cov kabmob tiv thaiv.

• Cov ncej uas sib tsoo loj loj.

Tsis muaj cov teeb cealing

Tus qauv ntsug yuav tsum tsis muaj lub foob.

Tsis muaj qhov kev ywj pheej

Sab saum toj thiab hauv qab inlet tsim yog qhov zoo tshaj plaws haum rau "Quaj" cov xwm txheej.

Tsis tshua muaj kev pheej hmoo ntawm kev thaiv

Lub inlets screen thiab impeller loj ntawm cov nqe lus txo qhov kev pheej hmoo ntawm kev thaiv.

Xoom Xoom Dej Ancillary Dej

Tus qauv ntsug cantilever nrog tsis muaj caj pas lossis submerged bearings zam kev xav tau cov caj dab uas kim heev lossis cov kabmob tawm.

Tsp / TspNtsug slurry twj tso kua miss kev ua haujlwm tsis tau

| Tus qauv | Sib Xws Paum P (kw) | Peev xwm Q (m3 / h) | Lub Taub Hau H (m) | Ceev n (r / min) | EFF.η (%) | Impeller dia. (hli) | Max.particles (hli) | Qho hnyav (kg) |

| 40pv-tsp (r) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-tsp (r) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-TSP (R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TSP (R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200sv-tsp (r) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250tv-tsp (r) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TSP (R) | 22-200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

Tsp / TspNtsug slurry twj tso kua misS Daim Ntawv Thov

Tus tsp / Tspr Viarry twj muaj muaj nyob rau hauv ntau qhov ntau thiab tsawg kom haum feem ntau cov kev siv lub tshuab nqus dej feem ntau. Tus tsp / TSPR cov twj tso kua yog ua pov thawj lawv txoj kev ntseeg tau, kev ua haujlwm thoob plaws, cov khoom siv hluav taws xob, cov xuab zeb thiab qhov chaw lossis qhov xwm txheej ntawm qhov teeb meem. Tus tsPR / TSPR tsim qauv nrog rau cov hlau tawv (TSP) lossis loj me me los ua rau nws zoo nkauj rau nws zoo rau kev ua haujlwm zoo nkauj thiab "

* TSP ntsug slurry twj thiab spares tsuas yog sib hloov tau nrog waran ® sp Ntsug slurry twj thiab spares.

Thnilevered, kab rov tav, centrifugal slurry twj tso kua mis khoom:

| Khoom Code | Cov lus piav qhia | Daim Ntawv Thov |

| A05 | 23% -30% CR DAWB Hlau | Impeller, liners, expeller, Ntiv nplhaib nthuav tawm, thawv ntawv, pes pob me, ncej phaj ntxig |

| A07 | 14% -18% CR DAWB Hlau | Impeller, liners |

| A49 | 27% -29% CR COV KHWV DAWB DAWB | Impeller, liners |

| A33 | 33% CRRISION & Corrosion Kuj Dawb Hlau Hlau | Impeller, liners |

| R55 | Ntuj Roj Hmab | Impeller, liners |

| R33 | Ntuj Roj Hmab | Impeller, liners |

| R26 | Ntuj Roj Hmab | Impeller, liners |

| R08 | Ntuj Roj Hmab | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| Tus G01 | Hlau Hlau Hlau Hlau | Tus ncej phaj, npog phaj, expeller, tus ntiv nplhaib nthuav tawm, tus kheej lub tsev, puag |

| D21 | Zas Hlau | Tus ncej phaj, npog phaj, cov kabmob lub tsev, puag |

| E05 | Cov Hlau Hlau | Tus pas |

| C21 | Stainless hlau, 4CR13 | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C22 | Tus Hlau Stainless, 304SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C23 | Tus Hlau Stainless, 316SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| S21 | Butyl roj hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S01 | EPDM Roj Hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S10 | Nitrile | Sib koom ua ke ib ncig, sib koom ua ke |

| S31 | Kev hypalon | Kev cuam tshuam, cov hnab tawg, lub nplhaib nthuav tawm, raug ntiab tawm, cov nplhaib sib koom ua ke, sib koom tes sib koom tes |

| S44 / K S42 | Neoprene | Impeller, liners, sib koom ua ke, sib koom ua ke |

| Sis | Koob hmoov | Sib koom ua ke ib ncig, sib koom ua ke |