Tshwj Xeeb Tsim Rau Cov Twj Tso Tawm Hauv Sawb Kev Kub Siab Twj Tso Kua Muag Rau Irrigation Submerged Twj

Peb lo rau peb txoj kev txhawb nqa ntawm "Zoo, Kev Ua Yeeb Yam, Innovation thiab Kev Ncaj Ncees". Peb lub hom phiaj los tsim ntau nqi rau peb cov kev cia siab nrog peb cov khoom siv nplua nuj, cov khoom siv tshiab rau cov khoom siv tshwj xeeb rau kev ua haujlwm siab, peb xav hauv qhov zoo tshaj qhov muaj nuj nqis. Ua ntej xa tawm los ntawm cov plaub hau muaj nruj heev tswj xyuas thaum kho raws li International Cov Qauv Zoo.

Peb lo rau peb txoj kev txhawb nqa ntawm "Zoo, Kev Ua Yeeb Yam, Innovation thiab Kev Ncaj Ncees". Peb lub hom phiaj los tsim ntau nqi ntxiv rau peb cov kev cia siab nrog peb cov kev cia siab, cov khoom siv tshiab, cov khoom muaj txiaj ntsig thiab cov kev pabcuam zoo rauSuav Teb Hidraulic slurry twj tso kua mis thiab roj hmab slurry twj tso kua mis, Peb cov khoom muaj peev xwm txuas ntxiv ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev muag khoom ua ntej ua ntej thiab tom qab muag ua kom muaj kev sib tw muaj zog nyob rau hauv kev ua lag luam thoob ntiaj teb. Txais tos cov neeg siv khoom tshiab thiab cov laus los ntawm txhua txoj kev ntawm lub neej los tiv tauj peb yav tom ntej kev ua lag luam thiab kev sib raug zoo!

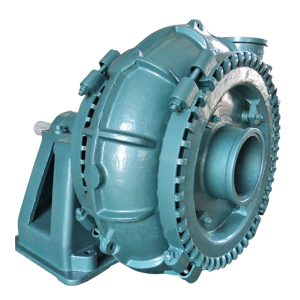

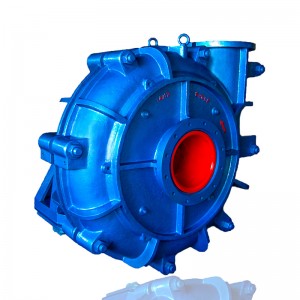

20/8 18Tu-Pa Roj Hmab Lined Slurry Twj Tso Kua MisNta ib cov kev sib cais-tsim qauv nrog pwm, hloov cov roj hmab tau hloov. Lub hnab ntim pwm yuav tau teev nyob rau hauv ntau yam ntuj thiab hluavtaws rubbers. Cov roj hmab roj hmab yog txheem. Cov kab ntawv muaj ntug dej-lub hardness ntawm 30-40 nrog lub tensile muaj zog, Coalrochemical, cov khoom siv hauv tsev, dredging, thiab lwm yam khoom siv thiab lwm yam.

Tsim nta:

√ Hnyav Ua Haujlwm Siv Nrog dhau-Bolt Tsim Qhia Tau yooj yim ntawm kev saib xyuas thiab qis dua cov hlua khi ua kom muaj zog, kev nyab xeeb, kev nyab xeeb, thiab lub neej ntev

Inch txoj kab loj, ua kom qeeb, muaj kev ua haujlwm siab tsim los ua tiav qhov siab tshaj plaws ntawm lub neej thiab cov nqi ua haujlwm tsawg

√ Loj loj, qhib cov nqe lus sab hauv los txo cov tsheb sab hauv, ua kom lub neej ua haujlwm zoo thiab txo qis

Roj hmab tuab los yog alloy bolt-hauv cov ntaub ua kom zoo dua corrosion respinor-tawm ntawm kev hloov pauv rov qab-tawm thiab sib hloov pauv cov nqi tswj hwm tag nrho thiab ua kom lub neej

√ Tsawg Tsawg Ncej Ncej / Impeller Overhang Txo Cov Ncauj Ncov Hnav Thiab Ua Rau Lub Neej

√ Cuptridge-style kev sib dhos tso cai rau kev saib xyuas hauv ib puag ncig huv si yam tsis muaj kev tshem tawm cov roj hmab slurry twj tso kua mis, ua rau muaj kev ua haujlwm txhim khu kev qha thiab ntev nqa lub neej

√ Roj lossis Roj Lubrication Cov Kabmob sib dhos sib dhos muaj kev yooj yim ntawm kev txij nkawm thiab txo qis qis

Yeem Qhuav khiav Ncej foob txo qis lossis tshem tawm cov dej ntws

√ Zoo siv tau ntev lub neej thaum txo lossis tshem tawm dej ntws yaug dej

20/18 St Pr Pr Brock Lined Slurry Twj Tso Cai:

20/18 STTxeebRoj Hmab Lined Slurry Twj Tso Kua Muag Khoom Tsis Txaus Siab:

| Tus qauv | Max. Hwjchim (kw) | Ntaub ntawv | Kev ua dej ntshiab | Tus tsis sib thab Vane No. | |||||

| Kab | Tus tsis sib thab | Peev xwm Q (m3 / h) | Lub Taub Hau H (m) | Ceev n (RPM) | EFF. η (%) | Nph (m) | |||

| 20/8 Looj-thr | 1200 | Yas | Yas | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 |

Roj Hmab Lined Slurry Twj Tso Cai Siv:

Tsuas & Kev Ua Haujlwm Hauv Ntxov

Lub qeeb khiav nrawm ntawm Tobee hnyav zog roj hmab twj tso kua mis, ua ke nrog cov kev xaiv ua ke thiab cov roj hmab, lub neej rau kev ua tiav thiab kev ua tiav kev sib cais.

Tshuaj Yeeb Nkab

Lub interchangability ntawm alloy thiab roj hmab Cheebtsam ua ke hauv tib lub taub hau roj hmab, ua ke nrog ntau yam kev xaiv nplua nuj rau kev xaiv tshuaj lom neeg.

Xuab zeb & gravel

Tsim los tsim kom yooj yim thiab yooj yim sawb thiab rov ua ke, Tobee hnyav kev xaiv roj hmab, ua rau nws xaiv qhov zoo tshaj plaws uas tsis muaj.

Qab Zib Ua

Txoj kev ntseeg tau zoo thiab pabcuam lub neej ntawm Tobee Hnyav Plaub Ntug Cov Roj Hmab Ua Haujlwm Hauv Cov Khaub Ncaws Hauv Qab Zib Lub sijhawm hauv cov dej qab zib yog qhov yuav tsum tau ua.

Flue Gas Desulphurisation

Lub cim tshiab ntawm kev ua haujlwm tshwj xeeb thiab kev kho mob corrosion, ua ke nrog cov roj hmab roj hmab tshiab heev, ua haujlwm rau tus neeg xa khoom loj heev raws li kev lag luam FGD.

Roj & Roj Tshawb Fawb

Tshaj ntau lub xyoo peb tau tsim cov ntawv pov thawj ntawm Tobee Hnyav Plaub Ntug Roj Hmab Twj Tso Rau Cov Kev Siv Tshwj Xeeb ntawm Cov Ntawv Thov Offshore. Tam sim no peb tuaj yeem muab cov kev daws teeb meem tshaj plaws rau sab saum toj rau kev hnav ris tsho.

Muaj Cov Ntawv Thov

Cov khoom tsis muaj peev xwm ua tau yog ua rau lub twj tso kua mis uas tsis muaj zog, hnav lub neej thiab kev ntseeg tau los coj cov qhua tuaj noj mov ntawm cov tswv cuab.

Nco tseg:

20/18 tu throur roj hmab slurry twj thiab cov chaw tsuas yog hloov pauv nrog waran ® 20/18 tu thined slurry twj thiab qhov chaw.

20/8 18Tu-Pa Roj Hmab Lined Slurry Twj Tso Kua MisNta ib cov kev sib cais-tsim qauv nrog pwm, hloov cov roj hmab tau hloov. Lub hnab ntim pwm yuav tau teev nyob rau hauv ntau yam ntuj thiab hluavtaws rubbers. Cov roj hmab roj hmab yog txheem. Cov kab ntawv muaj ntug dej-lub hardness ntawm 30-40 nrog lub tensile muaj zog, Coalrochemical, cov khoom siv hauv tsev, dredging, thiab lwm yam khoom siv thiab lwm yam.

Tsim nta:

√ Hnyav Ua Haujlwm Siv Nrog dhau-Bolt Tsim Qhia Tau yooj yim ntawm kev saib xyuas thiab qis dua cov hlua khi ua kom muaj zog, kev nyab xeeb, kev nyab xeeb, thiab lub neej ntev

Inch txoj kab loj, ua kom qeeb, muaj kev ua haujlwm siab tsim los ua tiav qhov siab tshaj plaws ntawm lub neej thiab cov nqi ua haujlwm tsawg

√ Loj loj, qhib cov nqe lus sab hauv los txo cov tsheb sab hauv, ua kom lub neej ua haujlwm zoo thiab txo qis

Roj hmab tuab los yog alloy bolt-hauv cov ntaub ua kom zoo dua corrosion respinor-tawm ntawm kev hloov pauv rov qab-tawm thiab sib hloov pauv cov nqi tswj hwm tag nrho thiab ua kom lub neej

√ Tsawg Tsawg Ncej Ncej / Impeller Overhang Txo Cov Ncauj Ncov Hnav Thiab Ua Rau Lub Neej

√ Cuptridge-style kev sib dhos tso cai rau kev saib xyuas hauv ib puag ncig huv si yam tsis muaj kev tshem tawm cov roj hmab slurry twj tso kua mis, ua rau muaj kev ua haujlwm txhim khu kev qha thiab ntev nqa lub neej

√ Roj lossis Roj Lubrication Cov Kabmob sib dhos sib dhos muaj kev yooj yim ntawm kev txij nkawm thiab txo qis qis

Yeem Qhuav khiav Ncej foob txo qis lossis tshem tawm cov dej ntws

√ Zoo siv tau ntev lub neej thaum txo lossis tshem tawm dej ntws yaug dej

20/18 St Pr Pr Brock Lined Slurry Twj Tso Cai:

20/18 STTxeebRoj Hmab Lined Slurry Twj Tso Kua Muag Khoom Tsis Txaus Siab:

| Tus qauv | Max. Hwjchim (kw) | Ntaub ntawv | Kev ua dej ntshiab | Tus tsis sib thab Vane No. | |||||

| Kab | Tus tsis sib thab | Peev xwm Q (m3 / h) | Lub Taub Hau H (m) | Ceev n (RPM) | EFF. η (%) | Nph (m) | |||

| 20/8 Looj-thr | 1200 | Yas | Yas | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 |

Roj Hmab Lined Slurry Twj Tso Cai Siv:

Tsuas & Kev Ua Haujlwm Hauv Ntxov

Lub qeeb khiav nrawm ntawm Tobee hnyav zog roj hmab twj tso kua mis, ua ke nrog cov kev xaiv ua ke thiab cov roj hmab, lub neej rau kev ua tiav thiab kev ua tiav kev sib cais.

Tshuaj Yeeb Nkab

Lub interchangability ntawm alloy thiab roj hmab Cheebtsam ua ke hauv tib lub taub hau roj hmab, ua ke nrog ntau yam kev xaiv nplua nuj rau kev xaiv tshuaj lom neeg.

Xuab zeb & gravel

Tsim los tsim kom yooj yim thiab yooj yim sawb thiab rov ua ke, Tobee hnyav kev xaiv roj hmab, ua rau nws xaiv qhov zoo tshaj plaws uas tsis muaj.

Qab Zib Ua

Txoj kev ntseeg tau zoo thiab pabcuam lub neej ntawm Tobee Hnyav Plaub Ntug Cov Roj Hmab Ua Haujlwm Hauv Cov Khaub Ncaws Hauv Qab Zib Lub sijhawm hauv cov dej qab zib yog qhov yuav tsum tau ua.

Flue Gas Desulphurisation

Lub cim tshiab ntawm kev ua haujlwm tshwj xeeb thiab kev kho mob corrosion, ua ke nrog cov roj hmab roj hmab tshiab heev, ua haujlwm rau tus neeg xa khoom loj heev raws li kev lag luam FGD.

Roj & Roj Tshawb Fawb

Tshaj ntau lub xyoo peb tau tsim cov ntawv pov thawj ntawm Tobee Hnyav Plaub Ntug Roj Hmab Twj Tso Rau Cov Kev Siv Tshwj Xeeb ntawm Cov Ntawv Thov Offshore. Tam sim no peb tuaj yeem muab cov kev daws teeb meem tshaj plaws rau sab saum toj rau kev hnav ris tsho.

Muaj Cov Ntawv Thov

Cov khoom tsis muaj peev xwm ua tau yog ua rau lub twj tso kua mis uas tsis muaj zog, hnav lub neej thiab kev ntseeg tau los coj cov qhua tuaj noj mov ntawm cov tswv cuab.

Nco tseg:

20/18 tu throur roj hmab slurry twj thiab cov chaw tsuas yog hloov pauv nrog waran ® 20/18 tu thined slurry twj thiab qhov chaw.

20/8 18Tu-Pa Roj Hmab Lined Slurry Twj Tso Kua MisNta ib cov kev sib cais-tsim qauv nrog pwm, hloov cov roj hmab tau hloov. Lub hnab ntim pwm yuav tau teev nyob rau hauv ntau yam ntuj thiab hluavtaws rubbers. Cov roj hmab roj hmab yog txheem. Cov kab ntawv muaj ntug dej-lub hardness ntawm 30-40 nrog lub tensile muaj zog, Coalrochemical, cov khoom siv hauv tsev, dredging, thiab lwm yam khoom siv thiab lwm yam.

Tsim nta:

√ Hnyav Ua Haujlwm Siv Nrog dhau-Bolt Tsim Qhia Tau yooj yim ntawm kev saib xyuas thiab qis dua cov hlua khi ua kom muaj zog, kev nyab xeeb, kev nyab xeeb, thiab lub neej ntev

Inch txoj kab loj, ua kom qeeb, muaj kev ua haujlwm siab tsim los ua tiav qhov siab tshaj plaws ntawm lub neej thiab cov nqi ua haujlwm tsawg

√ Loj loj, qhib cov nqe lus sab hauv los txo cov tsheb sab hauv, ua kom lub neej ua haujlwm zoo thiab txo qis

Roj hmab tuab los yog alloy bolt-hauv cov ntaub ua kom zoo dua corrosion respinor-tawm ntawm kev hloov pauv rov qab-tawm thiab sib hloov pauv cov nqi tswj hwm tag nrho thiab ua kom lub neej

√ Tsawg Tsawg Ncej Ncej / Impeller Overhang Txo Cov Ncauj Ncov Hnav Thiab Ua Rau Lub Neej

√ Cuptridge-style kev sib dhos tso cai rau kev saib xyuas hauv ib puag ncig huv si yam tsis muaj kev tshem tawm cov roj hmab slurry twj tso kua mis, ua rau muaj kev ua haujlwm txhim khu kev qha thiab ntev nqa lub neej

√ Roj lossis Roj Lubrication Cov Kabmob sib dhos sib dhos muaj kev yooj yim ntawm kev txij nkawm thiab txo qis qis

Yeem Qhuav khiav Ncej foob txo qis lossis tshem tawm cov dej ntws

√ Zoo siv tau ntev lub neej thaum txo lossis tshem tawm dej ntws yaug dej

20/18 St Pr Pr Brock Lined Slurry Twj Tso Cai:

20/18 STTxeebRoj Hmab Lined Slurry Twj Tso Kua Muag Khoom Tsis Txaus Siab:

| Tus qauv | Max. Hwjchim (kw) | Ntaub ntawv | Kev ua dej ntshiab | Tus tsis sib thab Vane No. | |||||

| Kab | Tus tsis sib thab | Peev xwm Q (m3 / h) | Lub Taub Hau H (m) | Ceev n (RPM) | EFF. η (%) | Nph (m) | |||

| 20/8 Looj-thr | 1200 | Yas | Yas | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 5 |

Roj Hmab Lined Slurry Twj Tso Cai Siv:

Tsuas & Kev Ua Haujlwm Hauv Ntxov

Lub qeeb khiav nrawm ntawm Tobee hnyav zog roj hmab twj tso kua mis, ua ke nrog cov kev xaiv ua ke thiab cov roj hmab, lub neej rau kev ua tiav thiab kev ua tiav kev sib cais.

Tshuaj Yeeb Nkab

Lub interchangability ntawm alloy thiab roj hmab Cheebtsam ua ke hauv tib lub taub hau roj hmab, ua ke nrog ntau yam kev xaiv nplua nuj rau kev xaiv tshuaj lom neeg.

Xuab zeb & gravel

Tsim los tsim kom yooj yim thiab yooj yim sawb thiab rov ua ke, Tobee hnyav kev xaiv roj hmab, ua rau nws xaiv qhov zoo tshaj plaws uas tsis muaj.

Qab Zib Ua

Txoj kev ntseeg tau zoo thiab pabcuam lub neej ntawm Tobee Hnyav Plaub Ntug Cov Roj Hmab Ua Haujlwm Hauv Cov Khaub Ncaws Hauv Qab Zib Lub sijhawm hauv cov dej qab zib yog qhov yuav tsum tau ua.

Flue Gas Desulphurisation

Lub cim tshiab ntawm kev ua haujlwm tshwj xeeb thiab kev kho mob corrosion, ua ke nrog cov roj hmab roj hmab tshiab heev, ua haujlwm rau tus neeg xa khoom loj heev raws li kev lag luam FGD.

Roj & Roj Tshawb Fawb

Tshaj ntau lub xyoo peb tau tsim cov ntawv pov thawj ntawm Tobee Hnyav Plaub Ntug Roj Hmab Twj Tso Rau Cov Kev Siv Tshwj Xeeb ntawm Cov Ntawv Thov Offshore. Tam sim no peb tuaj yeem muab cov kev daws teeb meem tshaj plaws rau sab saum toj rau kev hnav ris tsho.

Muaj Cov Ntawv Thov

Cov khoom tsis muaj peev xwm ua tau yog ua rau lub twj tso kua mis uas tsis muaj zog, hnav lub neej thiab kev ntseeg tau los coj cov qhua tuaj noj mov ntawm cov tswv cuab.

Nco tseg:

20/18 Tu thruple ntaub slurry twj thiab cov chaw tsuas yog hloov pauv nrog Warprise Lined Slepry Ris Dej ntawm "Zoo, Kev Ua Haujlwm, Kev Ua Haujlwm Tshiab, Kev Ua Lag Luam Tsim Tsa, Innovation thiab Kev Ncaj Ncees". Peb lub hom phiaj los tsim ntau nqi rau peb cov kev cia siab nrog peb cov khoom siv nplua nuj, cov khoom siv tshiab rau cov khoom siv tshwj xeeb rau kev ua haujlwm siab, peb xav hauv qhov zoo tshaj qhov muaj nuj nqis. Ua ntej xa tawm los ntawm cov plaub hau muaj nruj heev tswj xyuas thaum kho raws li International Cov Qauv Zoo.

Tshwj xeeb tsim rauSuav Teb Hidraulic slurry twj tso kua mis thiab roj hmab slurry twj tso kua mis, Peb cov khoom muaj peev xwm txuas ntxiv ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev muag khoom ua ntej ua ntej thiab tom qab muag ua kom muaj kev sib tw muaj zog nyob rau hauv kev ua lag luam thoob ntiaj teb. Txais tos cov neeg siv khoom tshiab thiab cov laus los ntawm txhua txoj kev ntawm lub neej los tiv tauj peb yav tom ntej kev ua lag luam thiab kev sib raug zoo!

Thnilevered, kab rov tav, centrifugal slurry twj tso kua mis khoom:

| Khoom Code | Cov lus piav qhia | Daim Ntawv Thov |

| A05 | 23% -30% CR DAWB Hlau | Impeller, liners, expeller, Ntiv nplhaib nthuav tawm, thawv ntawv, pes pob me, ncej phaj ntxig |

| A07 | 14% -18% CR DAWB Hlau | Impeller, liners |

| A49 | 27% -29% CR COV KHWV DAWB DAWB | Impeller, liners |

| A33 | 33% CRRISION & Corrosion Kuj Dawb Hlau Hlau | Impeller, liners |

| R55 | Ntuj Roj Hmab | Impeller, liners |

| R33 | Ntuj Roj Hmab | Impeller, liners |

| R26 | Ntuj Roj Hmab | Impeller, liners |

| R08 | Ntuj Roj Hmab | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| Tus G01 | Hlau Hlau Hlau Hlau | Tus ncej phaj, npog phaj, expeller, tus ntiv nplhaib nthuav tawm, tus kheej lub tsev, puag |

| D21 | Zas Hlau | Tus ncej phaj, npog phaj, cov kabmob lub tsev, puag |

| E05 | Cov Hlau Hlau | Tus pas |

| C21 | Stainless hlau, 4CR13 | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C22 | Tus Hlau Stainless, 304SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C23 | Tus Hlau Stainless, 316SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| S21 | Butyl roj hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S01 | EPDM Roj Hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S10 | Nitrile | Sib koom ua ke ib ncig, sib koom ua ke |

| S31 | Kev hypalon | Kev cuam tshuam, cov hnab tawg, lub nplhaib nthuav tawm, raug ntiab tawm, cov nplhaib sib koom ua ke, sib koom tes sib koom tes |

| S44 / K S42 | Neoprene | Impeller, liners, sib koom ua ke, sib koom ua ke |

| Sis | Koob hmoov | Sib koom ua ke ib ncig, sib koom ua ke |