Tus nqi tsim nyog rau cov hlau stainless / HLAU / THAUJ TOG LUB CEV / Kev Siv Cuam Tshuam / Carbon Hlau / OEM / CAV / Cais Moulding Casting / Twj Tso Kua Mis

Nrog rau cov neeg tau txais txiaj ntsig zoo, lub koob npe zoo thiab cov khoom siv rau hauv peb cov neeg siv khoom lag luam rau cov neeg siv khoom thoob ntiaj teb nrog cov khoom siv thoob ntiaj teb, peb cov khoom siv sib txawv, cov khoom siv sib tw, cov chaw ua haujlwm txaus siab.

Nrog kev ntseeg tau zoo, lub koob npe zoo heev thiab cov khoom tsim tau zoo heev, cov qauv tsim tawm los ntawm peb cov tuam txhab raug xa tawm mus rau ntau lub tebchaws thiab thaj chaw rauTuam Tshoj Forging Thiab Carbon Steel, Tsuas yog ua kom tiav cov khoom lag luam zoo kom tau raws li cov neeg siv khoom siv, txhua yam ntawm peb cov kev daws teeb meem tau raug kuaj xyuas ua ntej ua zaub mov xa tuaj. Peb ib txwm xav txog cov lus nug ntawm ib sab ntawm cov neeg siv khoom, vim tias koj yeej, peb yeej!

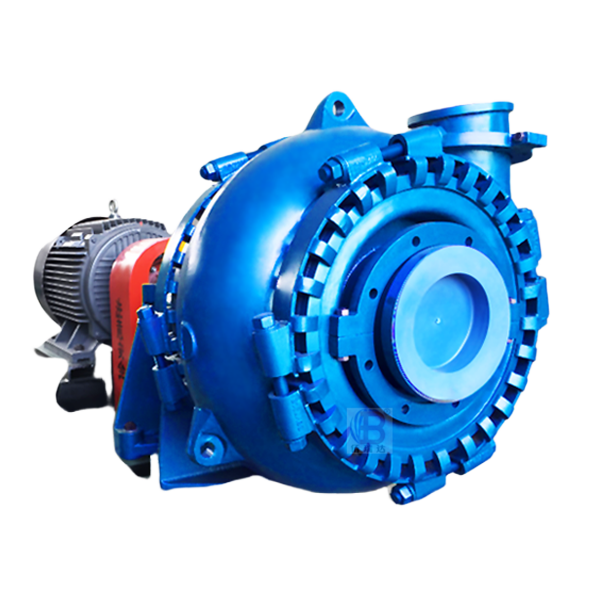

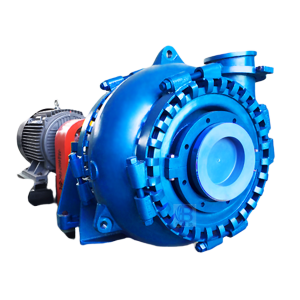

Cov twj TG / TGh Xuab Zeb Gravel twjyog tsim tshwj xeeb rau kev tso pa txuas ntxiv ntawm cov ntoo uas muaj zog heev, gavels, thiab xuab zeb. nrog qhov dav dav loj dua faib tawm. Muaj peev xwm tuav cov khoom loj ntawm cov khoom loj ntawm cov khoom siv high effecticencies tau ua rau tus nqi qis ntawm cov tswv cuab. Cov ntim loj hauv sab hauv profile ntawm lub casing txo cov velocities ntxiv kev nce ntxiv lub neej.

Tsim nta

√ Lub cim segmented clamp nplhaib rau cov chav me me thiab cov khoom sib hloov me me, txo qhov kev xav tau ntawm kev coj zoo. Yuav tsum tau tu tsawg kawg.

Impeller Tshem Tawm Tawm Vanes Txo cov qog siab thiab intrusion ntawm cov khoom siab ntawm cov khib nyiab hauv thaj chaw gland. Efficiency yog tswj los ntawm kev txo qis substing sab.

√ Tshwj xeeb tsim thiab ua qauv canneller vanes tso cai rau kev tuav ntawm cov khoom seem txawv txav. Cov cim tshwj xeeb tsim thiab muab cov vanes tiv thaiv cov khib nyiab abrasive ntawm lub ntsej muag sib khi.

√ Qhov loj, robust casing tau tsim los txo cov velocities ua rau muaj kev ua kom muaj kev ua tiav tsawg kawg thiab txhim kho lub neej. Lub casing yog ua los ntawm peb qho kev txwv kom txo lub sijhawm txij nkawm thiab cov nqi cuam tshuam nrog kev tsim qauv onepiece. (Tshwj tsis yog 6/4 dg uas muaj ob qho sib xyaw)

REITE DEAL HEASTE HWJ HWM COOCHER CRAPED Taper Cov Menyuam Cov Kabmob Cov Rooj Sib Tham yog haum raws li tus qauv. Ib qho kev sib tw loj hauv cov cheeb tsam nrog txo cov overhang minimizes defection thiab kev co hauv txhua qhov xwm txheej ua haujlwm tsis muaj teeb meem. Cov kev pabcuam tsis txaus ntseeg ua rau cov rooj sib txoos kom nqa txhua lub radial thiab axial thrustts.

√ Ib qho tshwj xeeb "-10" (khiav tawm 10) Kawg npog cov rooj sib txoos muaj ntawm v-singer nrog roj sab nraud nrog cov qauv nrog txhua lub twj txias

TG / TGh Xuab zeb Gravel twj ua haujlwm tsis

| Tus qauv | Max. Lub Hwj Huam P (kw) | Peev xwm Q (m3 / h) | Lub Taub Hau H (m) | Ceev n (r / min) | EFF. η (%) | Nph (m) | Impeller dia. (hli) |

| 6 / 4d-tg | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

| 6/2ee-TG | 120 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

| 8/6-TG | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 391 |

| 10 / 8s-tg | 560 | 216-936 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10 / 8s-tgh | 560 | 180-1440 | 24-80 | 500-950 | 72 | 2.5-5 | 711 |

| 10/8F-TG | 260 | 216-936 | 8-52 | 400-800 | 65 | 3-7.5 | 533 |

| 12 / 10f-tg | 260 | 360-1440 | 10-60 | 350-700 | 65 | 1.5-4.5 | 667 |

| 12/10g-tg | 600 | 360-1440 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10g-TGH | 600 | 288-2808 | 16-80 | 350-700 | 73 | 2-10 | 950 |

| 14 / 12g-tg | 600 | 576-3024 | 8-70 | 300-700 | 68 | 2-8 | 864 |

| 14 / 12t-tg | 1200 | 576-3024 | 8-70 | 300-700 | 68 | 2-8 | 864 |

| 16 / 14G-tg | 600 | 720-3600 | 18-455 | 300-500 | 70 | 3-9 | 1016 |

| 16/20T-TG | 1200 | 720-3600 | 18-455 | 300-500 | 70 | 3-9 | 1016 |

| 16 / 14TU-TGH | 1200 | 324-3600 | 26-70 | 300-500 | 72 | 3-6 | 1270 |

| 18/2TU-tg | 1200 | 720-4320 | 12-48 | 250-500 | 72 | 3-6 | 1067 |

Cov Kev Siv TG / TGh Xuab Zeb Gravel

TG / Tgh hnyav-Dutert-Dutert-Dutert-Dute catalically feem ntau haum rau cov nroj tsuag siab, ntau dua lub taub hau cyclone pub lossis ntev kev lag luam kev ua haujlwm thiab lwm yam kev lag luam.

Nco tseg:

* Tg Gravel twj thiab spares tsuas yog sib txuas nrog cov warman®G gravel twj thiab spares.Nrog rau cov neeg tau txais txiaj ntsig zoo, lub koob npe zoo thiab cov khoom siv rau hauv peb cov neeg siv khoom lag luam rau cov neeg siv khoom thoob ntiaj teb nrog cov khoom siv thoob ntiaj teb, peb cov khoom siv sib txawv, cov khoom siv sib tw, cov chaw ua haujlwm txaus siab.

Tus nqi tsim nyog rauTuam Tshoj Forging Thiab Carbon Steel, Tsuas yog ua kom tiav cov khoom lag luam zoo kom tau raws li cov neeg siv khoom siv, txhua yam ntawm peb cov kev daws teeb meem tau raug kuaj xyuas ua ntej ua zaub mov xa tuaj. Peb ib txwm xav txog cov lus nug ntawm ib sab ntawm cov neeg siv khoom, vim tias koj yeej, peb yeej!

Thnilevered, kab rov tav, centrifugal slurry twj tso kua mis khoom:

| Khoom Code | Cov lus piav qhia | Daim Ntawv Thov |

| A05 | 23% -30% CR DAWB Hlau | Impeller, liners, expeller, Ntiv nplhaib nthuav tawm, thawv ntawv, pes pob me, ncej phaj ntxig |

| A07 | 14% -18% CR DAWB Hlau | Impeller, liners |

| A49 | 27% -29% CR COV KHWV DAWB DAWB | Impeller, liners |

| A33 | 33% CRRISION & Corrosion Kuj Dawb Hlau Hlau | Impeller, liners |

| R55 | Ntuj Roj Hmab | Impeller, liners |

| R33 | Ntuj Roj Hmab | Impeller, liners |

| R26 | Ntuj Roj Hmab | Impeller, liners |

| R08 | Ntuj Roj Hmab | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| Tus G01 | Hlau Hlau Hlau Hlau | Tus ncej phaj, npog phaj, expeller, tus ntiv nplhaib nthuav tawm, tus kheej lub tsev, puag |

| D21 | Zas Hlau | Tus ncej phaj, npog phaj, cov kabmob lub tsev, puag |

| E05 | Cov Hlau Hlau | Tus pas |

| C21 | Stainless hlau, 4CR13 | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C22 | Tus Hlau Stainless, 304SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C23 | Tus Hlau Stainless, 316SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| S21 | Butyl roj hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S01 | EPDM Roj Hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S10 | Nitrile | Sib koom ua ke ib ncig, sib koom ua ke |

| S31 | Kev hypalon | Kev cuam tshuam, cov hnab tawg, lub nplhaib nthuav tawm, raug ntiab tawm, cov nplhaib sib koom ua ke, sib koom tes sib koom tes |

| S44 / K S42 | Neoprene | Impeller, liners, sib koom ua ke, sib koom ua ke |

| Sis | Koob hmoov | Sib koom ua ke ib ncig, sib koom ua ke |