Pheej Yig Pricelist Rau Casting Hastelloy Slurry Twj Npog Phaj Liner C 500 Linner C2110na

Uas muaj tus cwj pwm zoo thiab muaj kev txaus siab, muaj kev ntseeg siab, kev ntseeg siab, kev ua haujlwm tsim kho, thiab kev sib txuas lus tshwj xeeb, thiab kev sib txuas lus tshwj xeeb, thiab kev sib txuas lus zoo thiab ncaj ncees. Txais tos txhua tus phooj ywg ze rau tso kev sib txuas yuav mus ua lag luam ntev ntev.

Uas muaj tus cwj pwm zoo thiab muaj kev txaus siab, peb lub tuam txhab pheej txhim kho peb cov khoom lag luam zoo kom tau raws li cov khoom lag luam zoo, kev ntseeg tau, kev tsim kho ib puag ncig, thiab kev tsim kho tshiabTuam Tshoj Hastelloy slurry twj tso kua mis qhov chaw thiab twj tso kua mis, Peb cov neeg yuav khoom los ntawm ntau tshaj 20 lub teb chaws thiab peb lub koob npe tau raug lees paub los ntawm peb cov neeg siv khoom. Yeej tsis muaj kev txhim kho thiab siv zog rau 0% tsis txaus yog peb ob lub ntsiab kev cai zoo. Yuav tsum tau koj xav tau dab tsi, tsis txhob yig tiv tauj peb.

Slurry twj tso kua mis qhov chawyog hloov tau nrog AH / HH / L Txaus siab rau zoo kawg nkaus haum thiab ua tiav kom txo tau kev teeb tsa ua haujlwm.

Slurry twj sib txuas lus sib xyaw

√omnetely sib txuas nrog AH, AHR, HH, L kab rov quav kab, G, G, G, G, G, G, G, G, Line Grava Sand Twj, AF Hniav Slurry Twj thiab lwm yam

√Metal cov ntaub ntawv sau npe: A03, A04, A06, A07, A12, A45, A33, A49, A51, A61

Cov Khoom Siv Roj Hmab Roj Hmab Cim: R08, R24, R26, R33, R38, R38, R66

√Synthtic roj hmab cov ntaub ntawv code: S101, S10, S12, S21, S31, S42, S44, S504, S

√polyurethane cov ntaub ntawv code: U01, U05

√haft khoom siv: 45 #, 40crmo, SS304, SS316

√Hhaft tes tsho khoom: SS410, SS420 SS304, SS316

√Lantern nplhaib cov khoom siv: 304,316, PTFE

√bearing tsev / kabmob Kawg Npog Cov Khoom Siv: G01, D21

√expeller, expeller nplhaib: A05

√Muaj: Q05

Cov Ntaub Ntawv Khoom Piav Qhia

Hlau:

• KmtbCrr27 yog ib qho hnav tiv thaiv dawb cam khwb cia hlau uas muaj cov kev ua tau zoo nyob rau hauv cov lus qhia nyuaj.Qhov kev ua tau zoo tshaj plaws rau cov khoom siv acidic.

• KmtbCrr28 yog Martensitic Dawb Hlau nrog kev xav tsis thoob ntawm Chrome 28% yog ib qho kev ua kom dawb ntawm 430 yog qhov muaj zog ntawm 430 yog qhov kev hnav tawv dawb uas haum rau cov tsiaj huv tsis txaus, qhov twg yog qhov teeb meem erosive kuj yog ib qho teeb meem.

• KmtbCr35 yog tus hwm Yis Zog / Corrosion alloy, lub luag haujlwm tseem ceeb ntawm 450 hauv kev ua haujlwm zoo ntawm 450, cov pa roj ntsha, cov sulfuric acid, thiab lwm cov ntawv thov kom haum.

Cov ntaub ntawv customized:

Twj tso kua mis yog ib txwm ua kom zoo dua qub ntawm cov khoom zoo li cam khwb cia steel, hastellloy, titicoam, fluon, fluon, fluon, fluon, Blua, fluon, Blua, fluon, Blua, fluon, Blua, fluon, Buamic, Blua, Fluon, Blua, Buamic, Blua, Buamic, Blua, Buamic, Buamic, Fluon, Buamic, Bluor, Blua, Fluoron, Buamic, BluaCle, Bluor, Blua, Blua, Buamic, Blua, Fluon, Buasing, BluaCle, Blua, Fluoron, Buamic, Bluor, Buamic, Blua, Fluon, Buasing, Bluon, flui-ordbash & Corrosive cov ntaub ntawv rau ntau yam kev siv.

Slurry Twj Tso Cai Spare Xeem

Hnyav tsuas | ntxhia ua | Cov Kev Pab Cuam Tshuam | Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob | Cov Khoom Siv Hluav Taws Xob | Cov Khoom Noj Kom Zoo Dua | Cov Khoom Noj Khoom Haus Cov Khoom Noj Khoom Haus | Cov Khoom Noj Khoom Haus Cov Khoom Noj Ua Si | Cov ntawv thov | Nruam (qaj) Tim Tsis Muaj Zog | Cov Slurries Sururries | Cov Dej Kub | Cov Dej ntws | Ntxuav | Cov Khoom Siv Pem Teb | Sib tov

Nco tseg:

* Slurry twj spare xeem tsuas yog hloov pauv tau nrog waran®slurry twj spare xeem.Uas muaj tus cwj pwm zoo thiab muaj kev txaus siab, muaj kev ntseeg siab, kev ntseeg siab, kev ua haujlwm tsim kho, thiab kev sib txuas lus tshwj xeeb, thiab kev sib txuas lus tshwj xeeb, thiab kev sib txuas lus zoo thiab ncaj ncees. Txais tos txhua tus phooj ywg ze rau tso kev sib txuas yuav mus ua lag luam ntev ntev.

Pheej yig pricelist rauTuam Tshoj Hastelloy slurry twj tso kua mis qhov chaw thiab twj tso kua mis, Peb cov neeg yuav khoom los ntawm ntau tshaj 20 lub teb chaws thiab peb lub koob npe tau raug lees paub los ntawm peb cov neeg siv khoom. Yeej tsis muaj kev txhim kho thiab siv zog rau 0% tsis txaus yog peb ob lub ntsiab kev cai zoo. Yuav tsum tau koj xav tau dab tsi, tsis txhob yig tiv tauj peb.

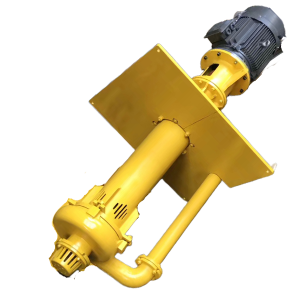

Thnilevered, kab rov tav, centrifugal slurry twj tso kua mis khoom:

| Khoom Code | Cov lus piav qhia | Daim Ntawv Thov |

| A05 | 23% -30% CR DAWB Hlau | Impeller, liners, expeller, Ntiv nplhaib nthuav tawm, thawv ntawv, pes pob me, ncej phaj ntxig |

| A07 | 14% -18% CR DAWB Hlau | Impeller, liners |

| A49 | 27% -29% CR COV KHWV DAWB DAWB | Impeller, liners |

| A33 | 33% CRRISION & Corrosion Kuj Dawb Hlau Hlau | Impeller, liners |

| R55 | Ntuj Roj Hmab | Impeller, liners |

| R33 | Ntuj Roj Hmab | Impeller, liners |

| R26 | Ntuj Roj Hmab | Impeller, liners |

| R08 | Ntuj Roj Hmab | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| Tus G01 | Hlau Hlau Hlau Hlau | Tus ncej phaj, npog phaj, expeller, tus ntiv nplhaib nthuav tawm, tus kheej lub tsev, puag |

| D21 | Zas Hlau | Tus ncej phaj, npog phaj, cov kabmob lub tsev, puag |

| E05 | Cov Hlau Hlau | Tus pas |

| C21 | Stainless hlau, 4CR13 | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C22 | Tus Hlau Stainless, 304SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| C23 | Tus Hlau Stainless, 316SS | Cov tsho ntxiv, teeb ci nplhaib, kev txwv tsis pub muaj caj dab, caj dab nplhaib, pob taws kub |

| S21 | Butyl roj hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S01 | EPDM Roj Hmab | Sib koom ua ke ib ncig, sib koom ua ke |

| S10 | Nitrile | Sib koom ua ke ib ncig, sib koom ua ke |

| S31 | Kev hypalon | Kev cuam tshuam, cov hnab tawg, lub nplhaib nthuav tawm, raug ntiab tawm, cov nplhaib sib koom ua ke, sib koom tes sib koom tes |

| S44 / K S42 | Neoprene | Impeller, liners, sib koom ua ke, sib koom ua ke |

| Sis | Koob hmoov | Sib koom ua ke ib ncig, sib koom ua ke |